Solar Photovoltaic

Solar Cells

The basic building unit of a photovoltaic system is a photovoltaic module, which in turn in made up of solar cells. A solar cell converts the light energy in sunlight into electricity by means of the photoelectric phenomenon found in certain types of materials such as silicon and selenium. When sunlight strikes on a solar cell, electrons are "excited" to become "free electrons" which can flow through an external circuit, and hence generate an electric current.

(Above: Animation showing working principle of solar cell)

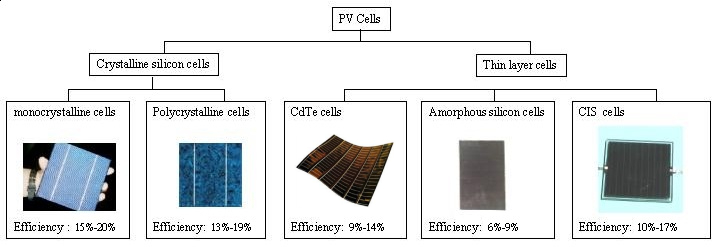

Solar cells in the market can be classified into two main categories - crystalline silicon cells and thin-film cells. Crystalline silicon cells can be further divided into mono-crystalline cells and poly-crystalline cells. Thin-film cells include the amorphous silicon cells, copper indium diselenide cells (CIS) and cadmium-telluride cells (CdTe). The classification of commercial solar cells can be summarized as follows:

(Sources for above: Monocrystalline cells - Fraunhofer Institute for Solar Energy Systems)

Polycrystalline cells - Lanitis Solar

CIS cells - Solar World)

The performance of a solar cell is expressed in terms of its "energy conversion efficiency", i.e. the efficiency in converting the energy in sunlight into electricity. The earliest silicon solar cells had efficiencies of just a few percents. Nowadays commercial solar cells can approach almost 20% in efficiency (with some special designs exceeding 20%), while special-made cells and experimental cells can exceed 30%. (It should be noted that efficiency of a photovoltaic module is lower than that of the constituent solar cells, and efficiency of a photovoltaic system is lower than that of the constituent photovoltaic modules, meaning that cell efficiency > module efficiency > system efficiency.)

Monocrystalline cells

Monocrystalline cells are made from thin slices (wafers) cut from a single crystal of silicon, which is produced by immersing a crystal nucleus with a defined orientation into a bath of melt-silicon and very slowing drawing the crytal from the bath. The wafer is doped with impurities to form p-type areas and n-type areas. After that, electrical leads are attached to the wafers, thus forming the monocrystalline cells. The cell efficiency of monocrystalline cells is in the range of 15% - 20%.

Polycrystalline cells

Polycrystalline cells are made from thin slices (wafers) cut from a cast silicon block. After doping the wafer with impurities and attaching electrical leads to the wafer, polycrystalline cells are formed. Since crystals of various orientations are formed during block casting, the surface of a polycrystalline cell has an appearance of shattered glass. The cell efficiency of polycrystalline cells is in the range of 13% - 19%.

Amorphous silicon cells

Amorphous cells are made by applying a thin layer (film) of active silicon on a solid substrate or flexible backing, typically a thin stainless steel sheet. After doping the wafer with impurities and attaching electrical leads to the wafer, polycrystalline cells are formed. The advantages of amorphous silicon cells include lower cost than that of crystalline cells, and can be applied on flexible and light-weight substrate. However, they have the disadvantage of lower efficiency and the problem of light-induced degradation. The module efficiency of amorphous silicon modules is in the range of 6% - 9%.

Copper indium diselenide cells (CIS cells)

The active semiconductor material of CIS cells is made from copper indium diselenide alloyed with gallium and/or sulphur. The CIS cells do not have the problem of light-induced degradation but they show stability problems in hot and humid environments. The module efficiency of CIS modules is between 10% - 17%, which is the highest among all thin-film technologies.

Cadmium telluride cells (CdTe cells)

CdTe cells are thin film cells with cadmium telluride as the active semiconductor material. The cadmium telluride layer acts as the p-type absorber layer and is coated on top of an n-type cadmium sulphide layer. The module efficiency of CdTe modules is between 9%-14%